Press release -

The pressure is on for manufacturers – more than half would prefer to give up in-house manufacturing – and thus risk losing a strategic competitive advantage

- Two out of three industry executives see severe cost and efficiency pressure on production

- More than 60 percent believe there are few opportunities to reduce these constraints

- Six megatrends offer an opportunity to reconfigure production and open up new competitive opportunities

Munich, March 2022: Faced constantly with new challenges, industrial companies have followed a proven strategy for decades: reduce costs, increase quality, and defend profit margins to persist in challenging markets. Although this approach has long been successful, it is now reaching its limits. Six megatrends are gaining in influence and redefining what makes production competitive: sustainability, industry disruption, regionalization, populism, customization, and digitalization. This is revealed in the latest study by Roland Berger “Next Generation Manufacturing”, for which 200 executives from ten key industries around the world were interviewed.

“The view of competitiveness in the manufacturing industry is changing from a largely cost-oriented approach to a more holistic one, in which CO2 emissions, political risks, or the increasing complexity of supply chains play a much bigger role,” says Marcus Berret, Global Managing Director at Roland Berger. “Companies that are restructuring their production now are giving themselves the chance to transform it from a burden into a competitive advantage.”

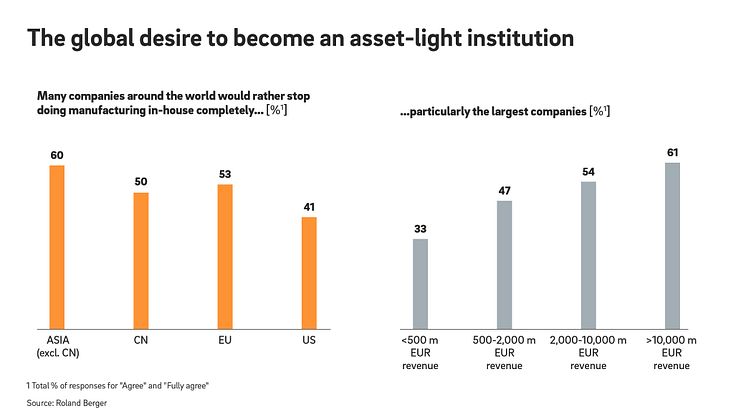

The switch to the asset-light principle diminishes competitiveness

67 percent of those asked stated that the manufacturing sector is under severe pressure to increase efficiency and reduce costs. More than half of the executives surveyed (51 percent) would therefore prefer to stop in-house manufacturing and implement an asset-light model. “Companies would rather focus on sales and marketing and outsource the actual assembly. However, this approach will only solve the ‘old-world’ problems. Outsourcing production may in fact harm, rather than aid, companies. In contrast, a restructuring of production taking into account megatrends such as sustainability, regionalization, or customization can create a competitive advantage,” says Oliver Knapp, Partner at Roland Berger.

Six megatrends encourage a rethink in manufacturing

Six megatrends are influencing manufacturing. While all the trends initially pose challenges for companies, they also offer an opportunity to set themselves apart from competitors and realign their production in the long run. Sustainability is the most important development. This is followed by regionalization: production sites are shifting closer to domestic markets, partly due to vulnerable supply chains, as well as consumers‘ increasing preference for regional products. The political environment is also intensifying in many countries, presenting risks for manufacturing companies that operate there. Furthermore, disruptive technologies are changing manufacturing processes, products, and consumption. Customization is the fifth megatrend. Customers want more individual or even unique products, subsequently leading to increased variations being manufactured. Last but not least, digitalization is permeating all areas of the economy and will also reshape manufacturing.

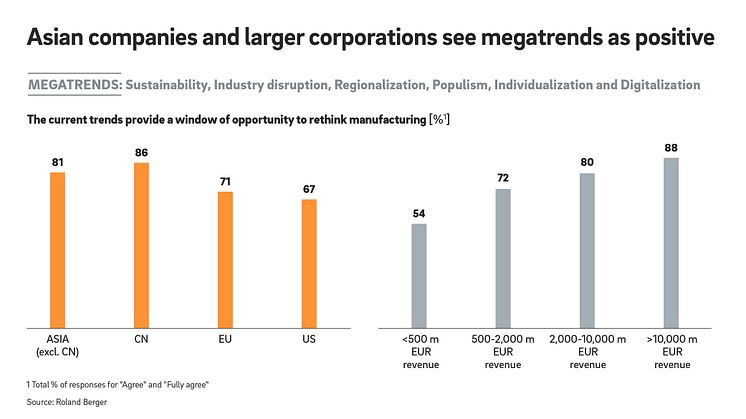

Asian firms and large companies view megatrends as positive

The survey revealed that executives of companies with a turnover of more than US$ 500 million felt under pressure more frequently than those of smaller firms (68 to 76 percent as opposed to 38 percent). However, these larger companies also saw these six trends as an opportunity to restructure manufacturing. In Eastern Asia, in particular, company directors are convinced of the opportunities the current trends will bring for reshaping their production: In China and the rest of Asia (excluding China), this figure was 86 and 81 percent respectively, while the EU reported 71 percent and the USA just 67 percent.

“To become a next generation manufacturer, companies can use different approaches. The first is to rethink their production networks. The growing demands on sustainability should be anchored in manufacturing and implementing digital production technologies. When restructuring their supplier networks, companies should establish new partnerships and forms of collaboration,” says Oliver Knapp.

Topics

Categories

Roland Berger is the only management consultancy of European heritage with a strong international footprint. As an independent firm, solely owned by our partners, we operate 50 offices in all major markets. Our 2400 employees offer a unique combination of an analytical approach and an empathic attitude. Driven by our values of entrepreneurship, excellence and empathy, we at Roland Berger are convinced that the world needs a new sustainable paradigm that takes the entire value cycle into account. Working in cross-competence teams across all relevant industries and business functions, we provide the best expertise to meet the profound challenges of today and tomorrow.